In commercial scenarios such as data centers, enterprise computer rooms, and laboratories, raised access floors are innovative flooring systems installed "off the ground" via specific support structures. With core advantages like flexible wiring management, load-bearing protection, and environmental adaptability, they have become key building materials in B2B procurement for engineering projects. However, facing scattered suppliers, diverse product specifications, and complex procurement links, many buyers often wonder: "Where to buy them?" and "How to choose reliable partners?" This article provides a full-process guide for B2B buyers—from product understanding to procurement execution—to help you efficiently find suitable purchasing channels and partners.

1. Introduction to Raised Access Floors

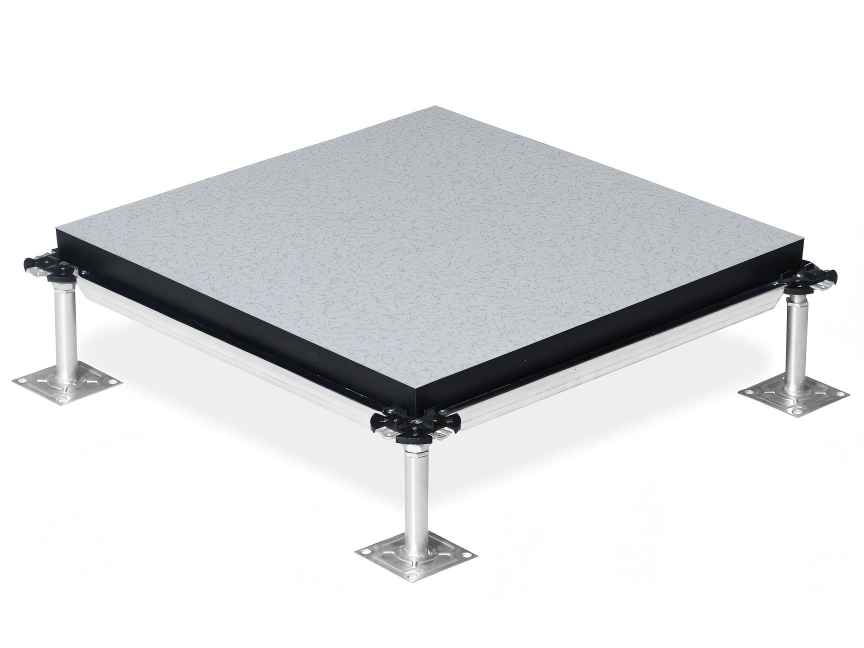

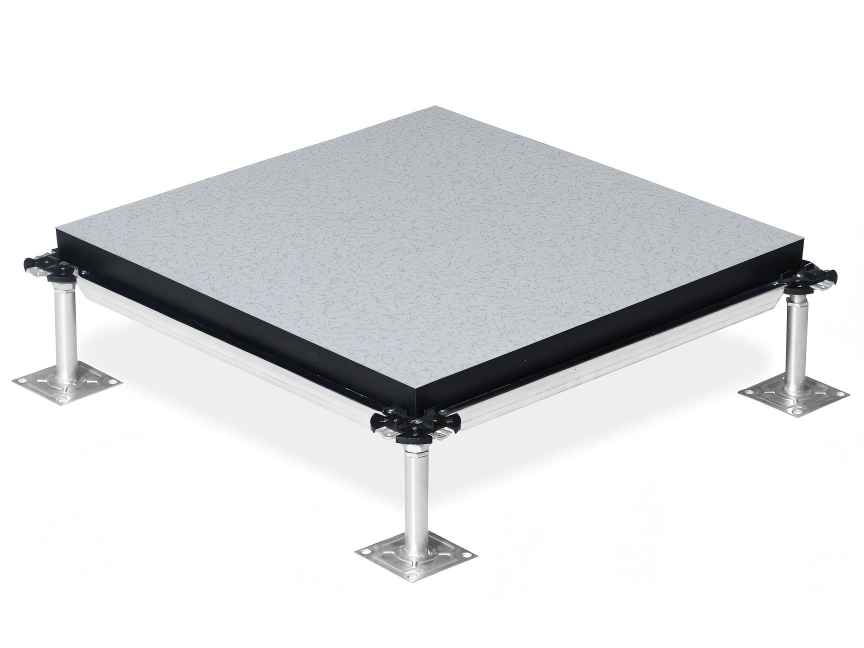

A raised access floor is a detachable flooring system with a reserved overhead space beneath it. It mainly consists of floor panels, supports, beams, and accessories (e.g., finishes, baseboards, edge strips). Its core functions include:

Removability: Panels and the support frame are connected via snaps or screws, allowing individual or multiple panels to be detached and reinstalled at any time without damaging the overall flooring structure.

Height Adjustability: The height of the support frame can be flexibly adjusted based on actual needs—from the standard 10cm-30cm to over 50cm (or higher) for large equipment installation—enabling adaptation to spatial requirements of different scenarios.

Flexible Wiring: The overhead space below can accommodate power lines, data cables, and air conditioning pipes, solving the "cluttered wiring" pain point in commercial spaces. No floor damage is needed for later maintenance.

Environmental Adaptability: Some products offer anti-static, fire-resistant, and moisture-proof properties, making them suitable for special scenarios like data centers (anti-static needs) and laboratories (corrosion resistance needs).

Load-Bearing & Durability: Standard commercial models can bear 300-1000kg per square meter. Steel and aluminum alloy products have a service life of over 10 years.

Modular Installation: Standardized panels (common sizes: 600×600mm, 800×800mm) support quick assembly and disassembly, facilitating space renovation.

By material, mainstream products include:

Steel raised access floors (cost-effective, high load-bearing)

Calcium sulfate floors (eco-friendly, soundproof)

Aluminum raised access floors (lightweight, corrosion-resistant, 100% recyclable)

Different materials are significantly suited to different scenarios, which is one of the core needs to clarify before procurement.

2. Understanding the Global B2B Raised Access Floor Market

As of 2024, the global B2B raised access floor market has exceeded $3.5 billion. It is expected to grow at a CAGR of 6.2% from 2025 to 2030, driven by core factors like data center construction (surge in global cloud computing demand), enterprise digital office upgrades, and laboratory infrastructure renovation.

From a regional market perspective:

Asia-Pacific: China, India, and Southeast Asia are core growth areas. Leveraging manufacturing advantages, China has become the world’s largest producer and consumer, accounting for over 40% of the global market share. Local suppliers (e.g., Huilian) offer "high cost-effectiveness + high customization" advantages.

North America & Europe: These markets have high maturity and strict requirements for product certifications (e.g., UL, CE). Buyers prefer suppliers offering integrated "brand + service" solutions.

Emerging Markets (Middle East, Africa): Demand is growing rapidly, but mainly for mid-to-low-end products. Procurement channels rely more on regional distributors and B2B e-commerce platforms.

The dispersion and regional differences of the global market mean B2B buyers must choose purchasing channels based on their own needs (e.g., order size, customization requirements, delivery cycle).

3. Key Factors to Consider Before Buying Raised Access Floors

Unlike retail, B2B procurement requires clarifying the following key factors first, from the three dimensions of "demand matching, cost control, and long-term use":

(1) Scenario & Performance Requirements

For data centers: Prioritize "anti-static performance (surface resistance 10^6-10^9Ω) + load-bearing capacity (concentrated load ≥ 500kg)".

For clean laboratories: Choose products with "anti-bacterial coatings + seamless splicing" to avoid dust accumulation.

For office areas: Focus on "sound insulation (airborne sound insulation ≥ 20dB) + aesthetics (custom wood grain/solid-color surfaces)".

(2) Specifications & Customization

Standard sizes (600×600mm, 800×800mm) have short procurement cycles and low costs. Special sizes (e.g., 1000×1000mm) require customization from manufacturers, usually taking 15-30 days.

Overhead height: Standard height is 300-500mm. For accommodating large air conditioning pipes, 600-1200mm support columns are needed—confirm technical feasibility with suppliers in advance.

(3) Cost & Budget

Cost composition: Product unit price (steel: ~80-150 RMB/sq.m; aluminum alloy: ~200-350 RMB/sq.m) + installation fee (15-30 RMB/sq.m) + logistics fee (varies by transportation distance; export includes customs duties and clearance fees).

Budget allocation: Avoid focusing solely on unit price. Reserve 10%-15% of the budget for later maintenance (e.g., accessory replacement, partial renovation).

(4) Compliance & Certifications

For domestic procurement: Confirm "ISO9001 quality certification + anti-static test report".

For export procurement: Comply with target market certifications (e.g., CE for Europe, UL for the US, BS for the UK) to avoid customs clearance delays due to missing certifications.

4. Procurement Channel Analysis: Where to Buy Raised Access Floors?

For B2B buyers with different needs (order size, customization requirements, regional scope), the following 4 channels have their own pros and cons—choose based on your needs:

(1) Direct Procurement from Manufacturers

Advantages: Low price (no middleman markup, 15%-25% lower than distributors), support for in-depth customization (e.g., special performance, exclusive logos), and direct access to technical teams for after-sales issues.

Suitable Scenarios: Large orders (usually ≥1000 sq.m), customization needs (e.g., special materials/sizes), long-term cooperative procurement (e.g., chain enterprises, data center operators).

Notes: Some manufacturers only produce in bulk and may not accept small orders (<500 sq.m)—confirm the minimum order quantity (MOQ) in advance.

(2) B2B E-Commerce Platforms

Mainstream Platforms: Alibaba (wide global coverage, many suppliers), Thomasnet (top choice for North American markets, focusing on industrial products), Made-in-China (concentrated Chinese suppliers, suitable for small-to-medium orders), Amazon Business (convenient for small-to-medium bulk procurement in Europe and the US).

Advantages: Easy filtering (filter by "material, certification, MOQ"), support for price comparison (connect with 3-5 suppliers simultaneously), and secure transactions (some platforms offer payment guarantees).

Suitable Scenarios: Small-to-medium orders (100-500 sq.m), first-time procurement (need to compare products quickly), scattered procurement regions (e.g., cross-border small enterprises).

Notes: Carefully verify supplier qualifications (e.g., platform certification, customer reviews). Prioritize "Gold Suppliers" or those with on-site factory certification to avoid trading with resellers.

(3) Regional Distributors/Agents

Advantages: Localized services (e.g., on-site measurement, fast delivery—usually 1-3 days in China), provision of installation teams (some distributors offer integrated "product + installation" packages), and fast after-sales response (accessory replacement can be coordinated the same day).

Suitable Scenarios: Urgent orders (e.g., emergency computer room renovation), small-batch procurement (<100 sq.m), need for localized installation and maintenance (e.g., offline stores, regional enterprises).

Notes: Prices are slightly higher than manufacturers. Confirm whether the brands they represent are genuine to avoid purchasing counterfeit products.

(4) Industry Exhibitions & Offline Networking

Key Global Exhibitions: DOMOTEX Asia (Shanghai, China—international flooring and paving technology exhibition), Surfaces (Las Vegas, US—international floor covering exhibition), HANNOVER MESSE (Hanover, Germany—industrial expo).

Advantages: On-site sample inspection (test load-bearing, texture), face-to-face communication with suppliers (understand factory strength), and access to the latest industry product trends (e.g., eco-friendly materials, smart floors).

Suitable Scenarios: Large customized orders (need to confirm sample quality), searching for long-term partners (on-site factory visits), understanding industry dynamics (e.g., new material technologies).

5. How to Evaluate Raised Access Floor Manufacturers & Suppliers

Regardless of the channel chosen, "evaluating supplier strength" is key to avoiding procurement risks. B2B buyers can establish an evaluation system from the following 5 dimensions:

(1) Qualifications & Certifications

Basic Certifications: ISO9001 (quality management), ISO14001 (environmental management). For special scenarios, additional test reports are required (e.g., anti-static per SJ/T 10796, fire resistance per GB 8624).

Export Qualifications: For overseas projects, confirm whether the supplier has import-export rights and can provide target market certifications (e.g., CE, UL) and customs clearance documents (e.g., commercial invoice, packing list).

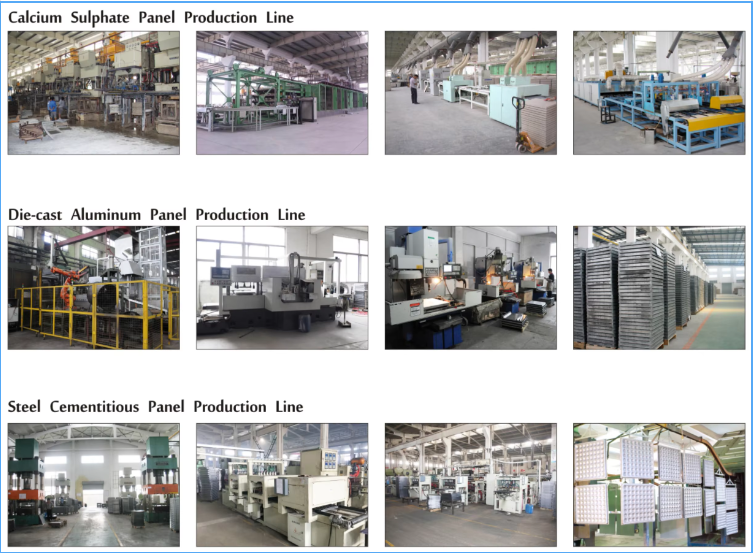

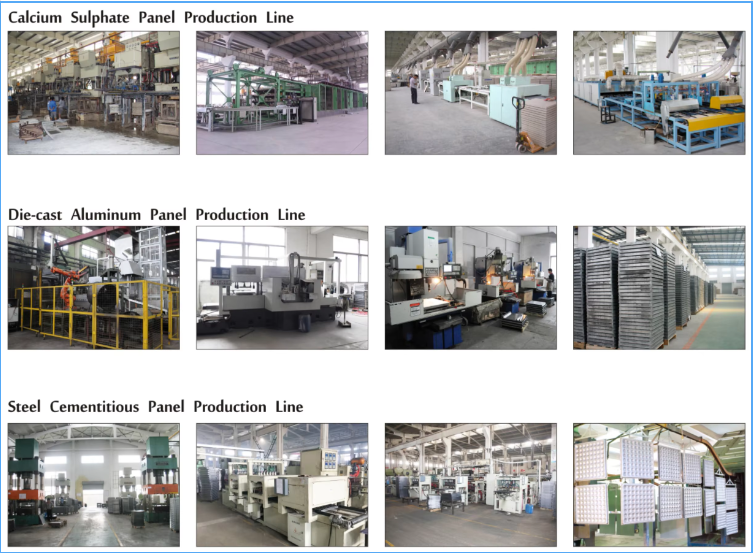

(2) Production & Supply Capacity

Factory Scale: Check if the supplier has its own production base (not just OEM), and the number of production lines (e.g., daily steel floor production capacity ≥5000 sq.m). Request factory videos or on-site visits.

Supply Chain Stability: Confirm if the supplier has fixed raw material suppliers (e.g., cold-rolled steel plates, calcium sulfate cores) and can cope with raw material price increases or shortages (e.g., provide a 6-month+ supply guarantee plan).

Delivery Cycle: Confirm if standard products can be shipped within 7-10 days and customized products within 30 days. Clarify delay compensation clauses in the contract.

(3) Cases & Reputation

Past Cases: Check if the supplier has served clients in your industry (e.g., for data center buyers: have they cooperated with Huawei or Tencent? For laboratory buyers: have they worked with universities or research institutions?). Request case photos or customer contact information to verify authenticity.

Customer Reviews: Check historical reviews on B2B platforms (focus on "quality problem rate" and "after-sales response speed"), or learn about reputation through industry associations and peer recommendations.

(4) Technical & After-Sales Services

Technical Support: Check if the supplier has a professional team providing full-process services (e.g., demand analysis, solution design, installation guidance—such as designing floor layout plans based on computer room layout).

After-Sales Service: Confirm the warranty period (1-3 years standard in the industry; 5 years for high-quality suppliers), warranty scope (covers installation issues and material wear?), and after-sales response time (24-hour response? Can local service points be coordinated in remote areas?).

(5) Price & Payment Terms

Price Reasonableness: Compare quotes from 3-5 suppliers. If a supplier’s price is more than 20% lower than the market average, be alert to "shoddy materials" (e.g., thin steel plates instead of thick ones).

Payment Terms: Standard B2B cooperation supports "30% advance payment + 70% payment after on-site acceptance". Avoid one-time full payment to reduce capital risks.

6. Why Choose Huilian as Your Trusted Manufacturer

In the global raised access floor market, Huilian has become a preferred partner for B2B buyers (especially in data centers and laboratories) over the past 10 years, thanks to its "in-depth technical expertise + full-link services". Its core advantages are reflected in the following 5 aspects:

(1) 20+ Years of Industry Experience, Guaranteed Quality

Jiangsu Huilian activity flooring Co., Ltd. was established more than 20 years, is China's largest activity flooring manufacturing company, Huilian with advanced manufacturing technology and rich manufacturing experience in many flooring companies stand out, the company over the years has always been consistent day, obsessed with the pursuit of product quality and service, is committed to providing customers with high-quality products and services. Huilian has its own factory covering an area of 20,000 square meters, with an annual production capacity of more than 1.5 million square meters, serving more than 50 countries and regions in Southeast Asia, the Americas, Europe, Australia and other countries and regions, serving more than 1,000 customers around the world, and has won wide praise from global customers, with cases covering the entire scene of data centers, laboratories, government and enterprise offices, etc. It has passed the tests of U.S. CISCA and U.K. MOB standards, and has been exported to more than 20 countries and regions in Europe, America and Asia-Pacific. It has been exported to more than 20 countries and regions in Europe, America, Asia-Pacific, and the United States, and the quality qualification rate has been maintained at more than 99.8% for five consecutive years.

Jiangsu Huilian activity flooring Co., Ltd. was established more than 20 years, is China's largest activity flooring manufacturing company, Huilian with advanced manufacturing technology and rich manufacturing experience in many flooring companies stand out, the company over the years has always been consistent day, obsessed with the pursuit of product quality and service, is committed to providing customers with high-quality products and services. Huilian has its own factory covering an area of 20,000 square meters, with an annual production capacity of more than 1.5 million square meters, serving more than 50 countries and regions in Southeast Asia, the Americas, Europe, Australia and other countries and regions, serving more than 1,000 customers around the world, and has won wide praise from global customers, with cases covering the entire scene of data centers, laboratories, government and enterprise offices, etc. It has passed the tests of U.S. CISCA and U.K. MOB standards, and has been exported to more than 20 countries and regions in Europe, America and Asia-Pacific. It has been exported to more than 20 countries and regions in Europe, America, Asia-Pacific, and the United States, and the quality qualification rate has been maintained at more than 99.8% for five consecutive years.

(2) Full-Material Product Line, Adapting to Diverse Needs

Huilian offers 4 major categories and over 20 sub-products (steel, calcium sulfate, aluminum alloy, wood). Whether you need "high-load-bearing anti-static steel floors" for data centers (concentrated load capacity up to 800kg), "anti-bacterial calcium sulfate floors" for laboratories (antibacterial rate ≥99%), or "custom wood-grain aluminum alloy floors" for offices, Huilian can meet your needs in one stop—no need to cooperate with multiple suppliers.

(3) High-Level Service Capabilities

Huilian always prioritizes customer satisfaction. It not only provides high-quality products but also creates a worry-free cooperation experience with thoughtful services:

Pre-Sales: A professional sales team with rich product knowledge and industry experience listens to your needs, provides detailed product consultation, and offers professional selection advice.

In-Sales: Strictly controls production progress and delivery time to ensure products arrive on time, in full, and with quality. It also provides professional installation guidance and technical support for smooth installation.

After-Sales: A comprehensive support system is in place. The after-sales team responds to any product issues immediately and arranges professionals to provide satisfactory solutions quickly.

(4) Flexible Cooperation Models, Reducing Procurement Costs

Huilian offers "tiered pricing" (90% discount for orders ≥5000 sq.m) and "long-term cooperation agreements" (free accessory supply for annual purchases ≥100,000 sq.m) for B2B buyers. It also provides "free sample delivery" (only freight required) and "free solution design" services to help buyers accurately match needs before procurement and avoid cost waste.

7. Procurement Process & Best Practices

(1) Standardized Procurement Process (Taking Direct Manufacturer Procurement as an Example)

1.Requirement Confirmation

Clarify the usage scenario (e.g., data center), product parameters (material: steel; size: 600×600mm; load-bearing: 500kg/sq.m), purchase quantity (1000 sq.m), budget (120,000 RMB), and delivery period (within 15 days).

2.Supplier Screening

Through industry exhibitions, peer recommendations, or B2B platforms, select 3-5 qualified manufacturers (e.g., Huilian) and request product manuals, certification reports, and past cases.

3.Sample Testing

Apply for free samples from target suppliers to test key performance (e.g., anti-static value, load-bearing capacity), and evaluate appearance and installation convenience.

4.Quote Comparison & Negotiation

Obtain quotes from each supplier, compare unit prices, logistics fees, installation fees, and warranty periods. Focus on negotiating "delivery delay compensation" and "warranty scope", then select the supplier with the best cost-effectiveness.

5.Contract Signing

Clarify product parameters, delivery time, payment terms (30% advance + 70% after on-site acceptance), warranty clauses (5-year warranty covering installation issues), and liability for breach of contract.

6.Production & Acceptance

The supplier starts production after receiving the advance payment. Conduct on-site acceptance upon delivery (check quantity, appearance, and performance tests), and pay the balance only after confirmation.

7.Installation & After-Sales

Coordinate the supplier’s installation team to enter the site. Conduct overall testing (e.g., random inspection of anti-static performance) after installation. Keep after-sales contact information for later maintenance.

(2) Procurement Best Practices

1.Prioritize Suppliers Offering Integrated "Product + Service"

Avoid split procurement (e.g., buying products separately and hiring a third party for installation) to reduce communication costs and liability disputes.

2.Value Sample Testing

Especially for special scenarios (e.g., laboratories), simulate actual usage environments for testing (e.g., acid and alkali corrosion resistance) to avoid quality issues after bulk procurement.

3.Clarify Contract Details

Specify "product parameter deviation range" (e.g., size error ≤1mm), "acceptance standards" (e.g., anti-static value compliant with SJ/T 10796), and "after-sales response time" (e.g., within 24 hours) in the contract.

4.Establish Long-Term Cooperation

Sign annual cooperation agreements with high-quality suppliers (e.g., Huilian) to enjoy better prices, faster delivery, and priority technical support—reducing long-term procurement costs.

8. Conclusion

For B2B buyers, the core answer to "where to buy raised access floors" is not a single channel, but "matching channels to needs":

For large customized orders: Prioritize direct procurement from manufacturers (e.g., Huilian).

For small-to-medium urgent orders: Consider regional distributors or B2B e-commerce platforms.

For first-time procurement: Visit industry exhibitions for on-site inspections.

The key to procurement lies in: first clarifying scenario and performance needs; then screening suppliers through the four-dimensional evaluation of "qualifications, production capacity, cases, and after-sales"; finally ensuring procurement safety through standardized processes and contracts.

As an 20year professional manufacturer, Huilian provides full-link services from demand design to after-sales maintenance. To learn more about products or obtain customized solutions, contact Huilian’s customer service team directly—we offer free consultation and sample delivery services.

To better adapt to your Google independent site’s target audience (e.g., North American or European buyers), do you need me to adjust the content—such as converting RMB to USD, adding region-specific certification standards, or optimizing keywords for SEO? I can also generate a localized version of the guide tailored to your key markets.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

नेपाली

Oʻzbekcha

latviešu

Azərbaycan dili

Euskara

Български

Català

ქართული

Hausa

Lietuvių

Jiangsu Huilian activity flooring Co., Ltd. was established more than 20 years, is China's largest activity flooring manufacturing company, Huilian with advanced manufacturing technology and rich manufacturing experience in many flooring companies stand out, the company over the years has always been consistent day, obsessed with the pursuit of product quality and service, is committed to providing customers with high-quality products and services. Huilian has its own factory covering an area of 20,000 square meters, with an annual production capacity of more than 1.5 million square meters, serving more than 50 countries and regions in Southeast Asia, the Americas, Europe, Australia and other countries and regions, serving more than 1,000 customers around the world, and has won wide praise from global customers, with cases covering the entire scene of data centers, laboratories, government and enterprise offices, etc. It has passed the tests of U.S. CISCA and U.K. MOB standards, and has been exported to more than 20 countries and regions in Europe, America and Asia-Pacific. It has been exported to more than 20 countries and regions in Europe, America, Asia-Pacific, and the United States, and the quality qualification rate has been maintained at more than 99.8% for five consecutive years.

Jiangsu Huilian activity flooring Co., Ltd. was established more than 20 years, is China's largest activity flooring manufacturing company, Huilian with advanced manufacturing technology and rich manufacturing experience in many flooring companies stand out, the company over the years has always been consistent day, obsessed with the pursuit of product quality and service, is committed to providing customers with high-quality products and services. Huilian has its own factory covering an area of 20,000 square meters, with an annual production capacity of more than 1.5 million square meters, serving more than 50 countries and regions in Southeast Asia, the Americas, Europe, Australia and other countries and regions, serving more than 1,000 customers around the world, and has won wide praise from global customers, with cases covering the entire scene of data centers, laboratories, government and enterprise offices, etc. It has passed the tests of U.S. CISCA and U.K. MOB standards, and has been exported to more than 20 countries and regions in Europe, America and Asia-Pacific. It has been exported to more than 20 countries and regions in Europe, America, Asia-Pacific, and the United States, and the quality qualification rate has been maintained at more than 99.8% for five consecutive years.