For those who are in contact with flooring materials for the first time, raised access flooring may be a bit strange - in the field of building flooring materials, rasied aceess flooring is a kind of flooring solution with special structure and function. It is not a plate that is directly attached to the ground like tiles or wooden floors, but an innovative flooring system that is "installed off the ground" through a specific support structure, which is especially suitable for places that require high functionality on the ground, such as machine rooms and laboratories. With the increasingly high functional requirements of the decoration program, the application of raised access floor is becoming more and more widespread.

If the tiles, wood flooring once paved on the "final word", then the rasied access floor is more like Lego blocks - can be lifted at any time, at any time to change the pattern. What does it really look like? Why is there always a "grid" to walk around in the computer room? 5 minutes to read this article, you will completely understand.

1. Core Definition: “Raised” is the Key

The core of the rasied access floor lies in the "rasied" structure, the principle of which is to support the floor panels stably above the original ground through the support framework composed of brackets and beams, thus forming a usable "overhead layer" between the panels and the original ground. The height of this overhead layer is not fixed, and can be adjusted according to the actual demand, the common height range from a few centimeters to tens of centimeters, and special scenarios can even reach more than one meter, which provides sufficient space for the subsequent laying of pipes and lines, and equipment installation. With ordinary flooring (such as ceramic tiles, wood flooring, plastic flooring) directly pasted or fixed to the ground at the grass-roots level is different, the raised access floor of the "off-ground design" breaks the ground and grass-roots level of the fixed connection mode, so that the ground from the "unchangeable decorative layer" into a "can be flexibly adjusted to the function of the carrier".

2.Three core features: the key to differentiating from ordinary flooring

(1) Removability

This is one of the most remarkable features of the raised accessfloor. As the panels are connected with the support frame by snap or screw, single or multiple panels can be disassembled and reassembled at any time without destroying the overall floor structure. For example, when the pipeline below the failure of maintenance, staff only need to remove the corresponding area of the panel, maintenance is completed and then reset the panel can be, the whole process will not have an impact on the appearance of the ground and the use of the surrounding areas; and ordinary flooring (such as ceramic tiles, solid wood flooring) once the paving is completed, if you need to repair the pipeline below the ground, you must destroy the paved floor, maintenance also need to be re-laid, not only the cost, but also affect normal use. High, but also affect the normal use.

(2) Height Adjustability

The height of the support frame can be flexibly adjusted according to the actual needs, from the conventional 10cm-30cm to more than 50cm or even higher to meet the needs of large equipment installation. This adjustability allows the raised access floor to adapt to the space requirements of different scenarios. For example, in data centers, in order to accommodate a large number of cables and air conditioning pipes, the height of the floor elevation is usually set at 30cm-50cm; while in ordinary offices, if only a small number of wires need to be laid, the height can be adjusted to 10cm-15cm, which not only meets the functional requirements, but also does not take up too much space.

(3) Convenient for pipeline laying and management

The raised floor becomes a natural “pipeline channel”. Power cables, network cables, air-conditioning water pipes, fire-fighting pipelines, etc. can be laid in the raised access floor without the need to open slots in the original ground for burying lines. This approach not only avoids the destruction of the building structure by floor grooving, but also makes the pipeline layout clearer, and subsequent maintenance, upgrading and replacement is also more convenient. On the contrary, ordinary flooring, pipelines usually need to be buried in the ground within the grass-roots level, once the pipeline problems or the need for upgrading, overhaul is extremely difficult, and may even need to refurbish the ground.

3. Key Components : each in its own way to ensure the stability of the system

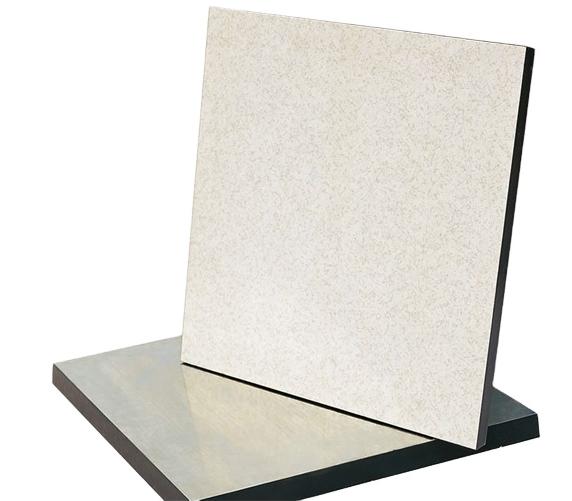

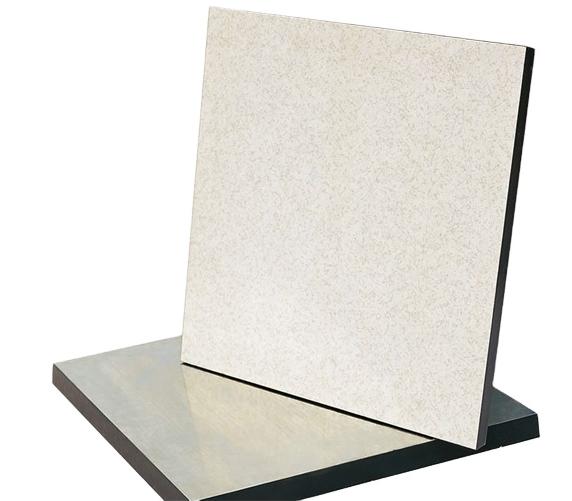

(1)Panel

As the “surface carrier” of the ground, in direct contact with the user and equipment, its material selection needs to be determined according to the needs of the use of the scene. Common panel materials include:

As the “surface carrier” of the ground, in direct contact with the user and equipment, its material selection needs to be determined according to the needs of the use of the scene. Common panel materials include:

All-steel anti-static panel: made of steel plate shell filled with foam cement core, with high strength, anti-static, fire, wear-resistant, etc., widely used in data centers, server rooms, electronic workshops, etc. on anti-static and load-bearing have high requirements of the place; Composite anti-static panel: particle board, fiberboard as a substrate, the surface of the anti-static veneer pasted on the surface of the relatively low-cost for the ordinary office, Laboratory and other anti-static have certain requirements, but the load-bearing needs of moderate scenes;

Aluminum alloy panel: processed using aluminum alloy material, light weight, high strength, corrosion resistance, applicable to the weight of the ground has strict restrictions, and the environment is more harsh places (such as chemical laboratories, humid environments)

Calcium sulfate panel: calcium sulfate as the main substrate, with excellent fire performance, environmental protection and good flatness, while the load-bearing capacity is strong, suitable for high fire level requirements, pay attention to environmental protection places, such as office buildings, hospitals, operating rooms, archives, libraries and so on;

Composite panels: Composite with a variety of materials, common substrates include particle board, fiberboard, mineral fiberboard, etc.. Its overall performance between all-steel panels and ordinary decorative flooring, moderate load-bearing, easy to install, suitable for the ground function of the basic requirements (such as mild anti-static, daily wear-resistant), but limited budget scenarios, such as ordinary offices, training rooms, small computer rooms, etc.;

(2)Pedestal

As the “supporting skeleton” of the whole ground system, it is responsible for transferring the weight of the panels to the original ground, and at the same time determines the height of the overhead. Brackets can be categorized into different grades according to their load-bearing capacity. Commonly, there are light pedestals (load-bearing within 500kg), mediumpedestals (load-bearing 500kg-1000kg) and heavy pedestals (load-bearing more than 1000kg).You can choose the corresponding grade of pedestal according to the weight of the ground-carrying equipment (e.g., server cabinets, large instruments) to ensure the load-bearing safety of the ground system.

As the “supporting skeleton” of the whole ground system, it is responsible for transferring the weight of the panels to the original ground, and at the same time determines the height of the overhead. Brackets can be categorized into different grades according to their load-bearing capacity. Commonly, there are light pedestals (load-bearing within 500kg), mediumpedestals (load-bearing 500kg-1000kg) and heavy pedestals (load-bearing more than 1000kg).You can choose the corresponding grade of pedestal according to the weight of the ground-carrying equipment (e.g., server cabinets, large instruments) to ensure the load-bearing safety of the ground system.

(3)Stringer

The “ties” connecting adjacent pedestals, together with the pedestals, form a stable support framework to prevent the pedestals from shifting, and at the same time play an auxiliary support role for the panels to enhance the flatness and stability of the panels. The crossbeam is usually used in conjunction with the pedestal, and the material is mostly steel, with rust-proof surface treatment to adapt to the humid environment that may exist in the overhead floor and prolong the service life.

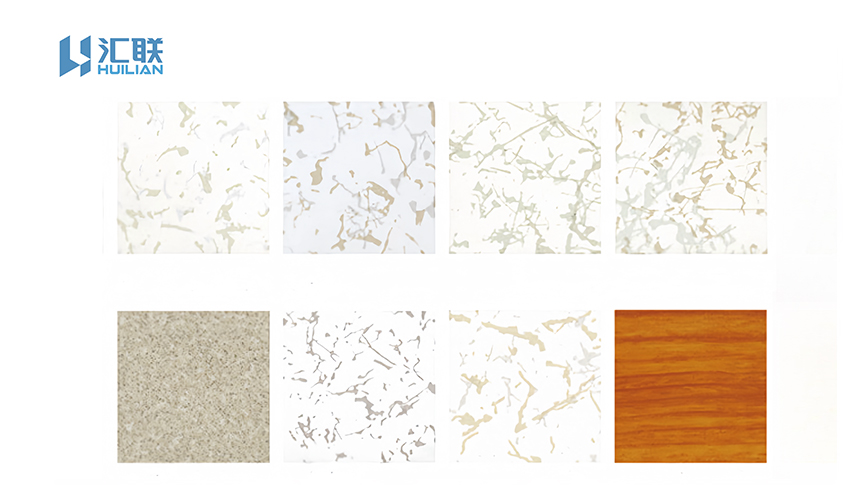

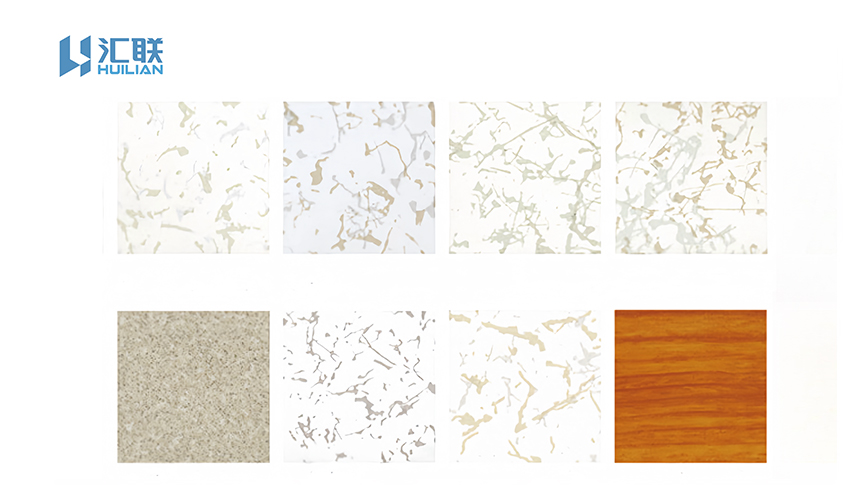

(4)Finish

Common raised access floor finishes are anti-static finishes (including HPL veneer, PVC veneer, anti-static tile veneer), and architectural finishies (including natural wood veneer, marble veneer, ceramic tile veneer, carpet tile veneer, etc.). You can choose the right floor finish according to different environmental needs and decoration styles.

(5)Accessories

The “detail additions” that guarantee the integrity and aesthetics of the floor system mainly include:

Skirting: Installed at the junction of the wall and the panel, it covers the gap between the panel and the wall, prevents dust from entering the overhead, and at the same time enhances the aesthetics of the floor-wall interface;

Halving strip: Used at the junction of the floor system and other floor materials (such as ordinary floor, floor tiles), or the edge of the ground (such as steps, ramps), to play the role of transition, closure and protection, to avoid damage to the edge of the panel;

Anti-static grounding accessories: including grounding bolts, grounding wires, etc., are used to connect metal components such as panels and brackets to the grounding system to ensure the anti-static performance of the entire ground system and prevent static electricity from interfering with or damaging the equipment.

4.Comparison with traditional flooring

With all kinds of places on the ground functionality, flexibility and ease of maintenance requirements continue to improve, raised access floor by virtue of its unique advantages, is gradually replacing the ordinary ground, become the first choice for data centers, laboratories, offices, command centers and other places of the ground solution.

Comparison Dimension |

Raised Access Flooring |

Conventional Flooring (Ceramic / Solid Wood / Vinyl) |

| Pipeline Maintenance |

Panels are detachable, allowing direct maintenance of pipelines in the raised layer. Maintenance time is short (usually 1-2 hours per location) with no floor damage. |

To maintain pre-embedded pipelines, the installed flooring must be damaged. Maintenance time is long (usually 1-3 days per location), and the floor needs to be re-laid, resulting in high costs. |

| Space Reusability |

90%The pipeline layout in the raised layer can be flexibly adjusted, and the floor can be repurposed at any time (e.g., converting an office to a server room) with a reusability rate of over 90%. |

Pre-embedded pipelines are fixed; repurposing the floor requires large-scale renovation, with a low reusability rate (usually below 30%). |

| Load-Bearing Capacity |

Custom heavy-duty supports are available, with a load-bearing capacity of over 1000kg/m², meeting the needs of heavy equipment (e.g., server racks). |

The conventional load-bearing capacity is 200-500kg/m². Additional floor reinforcement is required for heavy equipment, which is costly and affects aesthetics. |

| Environmental Adaptability |

Panels with anti-static, fire-resistant, waterproof, and corrosion-resistant properties can be equipped, adapting to multiple scenarios (e.g., server rooms, laboratories, humid environments. |

Anti-static treatment requires extra work; fire resistance, waterproofness, and corrosion resistance are limited. Customized flooring is needed for special environments, leading to high costs. |

| Installation Convenience |

Modular installation requires no floor grooving; a 100m² space can usually be completed in 1-2 days. |

The floor base needs to be prepared first (leveling, grooving for pipeline embedding) before laying the flooring. A 100m² space usually takes 3-5 days to complete with complex procedures. |

| Long-Term Costs |

Low maintenance costs (approximately 5-10 yuan/m² per year) with a service life of 15-20 years. |

High maintenance costs (approximately 20-50 yuan/m² per year) with a service life of 5-10 years, requiring regular replacement. |

From the table, it can be clearly seen that in the scenarios with high requirements for functionality and flexibility, the advantages of raised access floors far exceed those of ordinary floors, especially in terms of pipeline maintenance, space reuse and load-bearing capacity, with which ordinary floors are almost incapable of competing.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

Bahasa Melayu

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

नेपाली

Oʻzbekcha

latviešu

Azərbaycan dili

Euskara

Български

Català

ქართული

Hausa

Lietuvių